Social Engineering Techniques

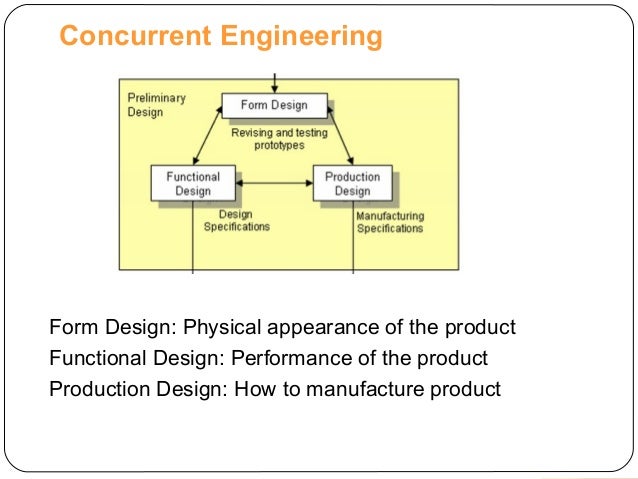

Read the latest chapters of Control and Dynamic Systems at ScienceDirect.com, Elsevier’s leading platform of peer-reviewed scholarly literature. In this article a study of state of the art of the concurrent engineering technique in the automotive industry is presented. The importance and benefits of.

The practice is said to be a strategy designed to avoid damage and wear to the car and the necessity of paying a pit crew while still collecting prize money. Opponents of the new system argue that this promotes controversial 'start and park' tactics where a team will start the race, run a few laps, then call it a day and head to the garage. Nascar earnings per race. Under the current system, it's possible that a driver who finishes in last place may earn more money than someone else who fared far better. Why do such a thing?

How Toyota’s product design and development process helps find the best solutions and develop successful products. Advertisement Toyota Motor Corporation is an industry leader in product development lead time while using fewer engineers than its U.S. It has also shown remarkable consistency in market share growth and profit per vehicle, which led to cash reserves of $21 billion, exceeding those of the “Big Three” automakers combined. The Toyota Production System (TPS), dubbed “lean manufacturing,” has been critical in these accomplishments, but we believe that Toyota’s product design and development system is also an important contributor.